Our commitment: Nothing is more important than the safety and health of people who work in the steel industry.

- This commitment, strongly endorsed by the worldsteel Board of Members, is accompanied by a set of six principles.

- Protecting the safety and health of everyone who works in or around the steel industry is of vital importance to all our members. The duty of care and social responsibility demands that everyone is able to work in a safe and healthy work environment.

- Worldsteel provides up-to-date guidance, data, processes and procedures freely available to members to help the steel industry deliver on its key mission to eliminate accidents and manage working environments with the highest standards of safety and health conditions.

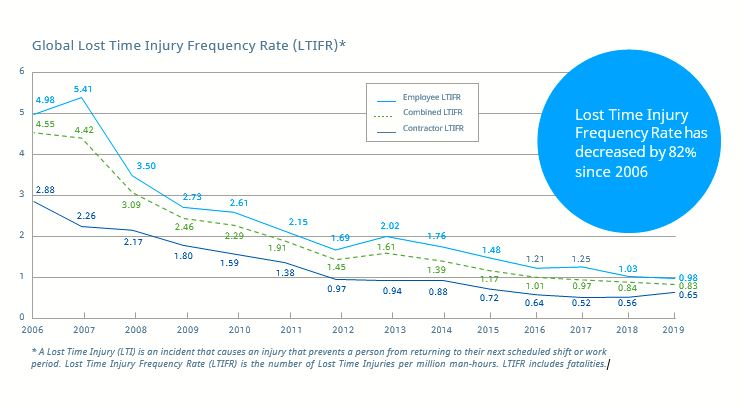

- Safety data collected from our membership show that the steel industry has seen a steady and notable reduction in the Lost Time Injury

- Frequency Rate (LTIFR) over the past decade. The injury rate per million hours worked has decreased from 4.55 in 2006 to 0.83 in 2019, a reduction of 82%.

- Although our Lost Time Injury Frequency Rate statistics are promising, an integrated focus, including leading and lagging indicators, is required to gain a greater insight into the safety and health performance of the industry.

Four key focus steel industry

Four key areas must be considered to manage safety and health comprehensively:

1. Safety culture and leadership

- A sound organizational culture has safety embedded. Attitudes and behaviors that support the goal of zero harm typically contribute to safer operations and better overall company results.

- Attitudes and behaviors that support the goal of zero harm typically contribute to safer operations and better overall company results.

- These are deeply reflected in the actions of employees and contractors. Newcomers embrace and internalize these values in order to remain and grow in the organization.

- Effective leadership is critical to achieving and sustaining a positive safety culture.

- A strong and visible commitment from the very top of the company shared by all levels of management is essential to achieve a healthy accident-free workplace.

- Steel companies that have the best safety records are those whose chief executives are held accountable by the board of directors for the safety and health of all people working on their sites, employees and contractors alike. These are companies where all levels of management are actively involved and support a safe and healthy approach to work on the shop floor.

2. Occupational safety management promotes the safety of employees, contractors and visitors by preventing personal injuries in the workplace, and has a strong focus on primary prevention of exposure to hazards.

3. Occupational health management

In its widest definition, occupational health management encompasses the physical, mental and social well-being of the people working in the company. The focus is placed on the long-term effects of exposure to hazards. The health of workers has several determinants, including risk factors at the workplace leading to cancers, musculoskeletal diseases, respiratory diseases, hearing loss, circulatory diseases, stress-related disorders and others.

4. Process safety management

- Process safety is a blend of engineering, operations and management skills focused on preventing catastrophic accidents, particularly structural collapse, explosions, fires and toxic releases associated with loss of containment of energy or dangerous substances such as toxic gases, molten metal, chemicals and petroleum products.

- The manufacturing of steel involves processes with intrinsic hazards that need careful management.

- The measures needed to control these hazards are often complex. The focus of process safety management is not limited to protecting the people within the company but also includes the environment, assets and surrounding community.

Sourced: worldsteel.org

OUR FABRICATION PROCESS

If you want reliable steel parts, contact the experts at AM Industries Vietnam. Our processes include stamping, welding, folding, bending, and finishing to match our exact requirements.

Working as a solution provider, at AM Industries Vietnam, we are completely focused on our approach and it is reflected in our business process. Due to our committed approach, we are highly trusted by our clients.

It has further helped us to achieve a respectful position among our competitors. AM’s a dynamic company and it is conquering big markets through its two primary strategies: Total quality & Flexibility.

We believe in an industrial world made of trust, passionate and dedicated people. We word to achieve this with an open-minded, quick and customer-centered approach.

Want to learn more about our steel fabrication services in Vietnam? Contact us today for a quote based on your requirements. If you need help, our experienced engineers are available to help determine the requirements for your specific project.

Please feel free to get in touch with us for all your inquiries.