Structural steel beam and column are essential components in the construction of buildings and other structures that help distribute weight and support heavy loads in buildings and other constructions. But to the uninitiated, the differences between these seemingly similar steel structures may not be obvious.

Understanding the difference between steel beam and steel column is vital for architects, engineers, and anyone planning a building project. This post dives into the important differences between steel beam and column, helping you understand their unique role in supporting the weight of your construction project.

WHAT IS THE DIFFERENCE BETWEEN STEEL COLUMN AND BEAM?

1. Structural Steel Beam: Carrying the Load Horizontally

Imagine the floors and ceilings of a building. Steel beams act as horizontal supports, connecting walls, columns or foundations. They transfer force from one point to another, ensuring even distribution over their length.

In construction, these beams play an important role in supporting the structural load and transmitting that load to columns or other support points. These beams boast exceptional strength-to-weight ratios, allowing for long spans and open floor plans.

1.1 Types of Steel Beams:

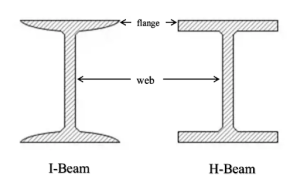

- I-Beams (or Wide Flange Beams):

| They are the most widely used beam, I-beams are hot-rolled sections. They are the most widely used beam, I-beams are hot-rolled sections. They consist of a flat, wide web with flanges on either side.

This design offers excellent strength and weight efficiency, making them suitable for long spans in buildings, bridges, and other structures. |

|

- H-Beams:

| Similar to I-beams but with equal height and width. H-beams are ideal for high-rise buildings, stadiums, and other projects requiring exceptional strength. |  |

- Channel Beams (C-Beams or U-Channels):

| Channel beams resemble a letter “C” in profile. They offer good lateral strength and are commonly used for lintels over doorways and windows, supporting purlins in roofs, and for creating built-up sections |  |

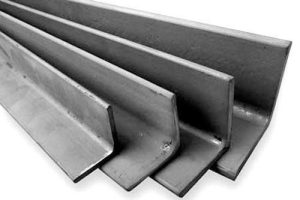

- Angle Beams: (L-Beams):

| L-shaped in cross-section, angle beams are versatile and can be used for various purposes, including supporting non-structural elements like cladding or shelves, creating braces and connections, and acting as edging for concrete slabs. |  |

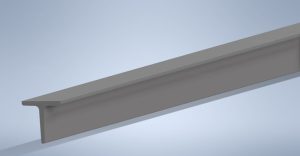

- T-Beams:

| T-beams have a flange on one side and a web on the other, forming a capital “T” shape. They are often used in bridges and floor systems. T-beams can also be used as standalone beams for shorter spans. |  |

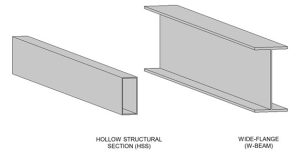

- Hollow Structural Sections (HSS):

| HSS are typically manufactured from high-strength steel, rectangular or circular hollow beams. |  |

1.2 Advantages and applications of steel beams:

Steel beams possess many advantages that make them a popular choice for construction projects compared to other construction materials:

- Exceptional durability: Steel beams exhibit outstanding strength, allowing them to withstand heavy loads without significant deformation.

- Design Flexibility: Different shapes and sizes of steel beams give architects and engineers design flexibility, meeting different structural requirements.

- Durable and long-lasting: Steel beams have a long service life and are resistant to damage, corrosion, and pests, contributing to the longevity of the building.

Due to these advantages, they are crucial components in various construction projects, including:

- Buildings: Supporting floors, roofs, and walls in residential, commercial, and industrial structures.

- Bridges: The main support structure for carrying traffic across spans.

- Stadiums and arenas: Supporting the roof structure and seating areas.

- Parking garages: Supporting multiple levels of vehicles.

- Shipbuilding: Providing the framework for the hull and decks

1.3 How to choose the right steel beam for your project:

Selecting the appropriate steel beams for your project requires considering several factors:

- Load capacity: The beam needs to be strong enough to support the weight it will carry (dead loads from the structure itself and live loads from occupants or equipment). A structural engineer will calculate the required load capacity.

- Span: The distance the beam needs to bridge between supports. Beams with larger depths can typically span longer distances.

- Deflection: The amount the beam will bend under load. This needs to be controlled to maintain functionality and aesthetics.

- Fire resistance: In some cases, fire-resistant coatings or specific beam designs may be required for safety.

- Cost: Wider, deeper, or thicker beams with higher strength steel will generally be more expensive.

2. Steel Column: The Pillars of Strength

For steel beams that support horizontally, steel columns act as pillars of strength supporting everything vertically. Their primary function is to safely transfer loads vertically, ensuring stability and preventing collapse.

They carry the weight of the entire structure above them, including floors, ceilings, and the roof. This load is then transferred down to the foundation.

2.1 Types of Steel Columns:

- Wide Flange Columns (H-columns): These are essentially H-shaped beams used in a vertical orientation, which offers excellent strength in both resisting compressive forces and bending moments. They are a popular choice for high-rise buildings, long-span structures, and applications requiring high load capacities.

- Square or Rectangular Hollow Sections (SHS/RHS): These are versatile columns with a hollow core and square or rectangular shape. They offer good strength-to-weight ratio and are easy to fabricate. Commonly used in buildings, bridges, and industrial structures.

- Circular Hollow Sections (CHS): Strong and lightweight, CHS columns are ideal for applications where aesthetics and high load-bearing capacity are required. They are commonly used in stadiums, auditoriums, and for architectural purposes due to their clean look.

- L-shaped columns: Simple to fabricate and offer good bi-axial bending strength, making them suitable for supporting walls and beams in buildings and other structures.

- Composite columns: Combine steel sections with concrete to create a high-strength, fire-resistant column. The concrete core improves the fire performance of the steel, while the steel section provides additional strength. Used in high-rise buildings and other structures requiring high load capacity and fire resistance.

2.2 Advantages and applications of steel columns:

These several types of steel columns have their own advantages and applications like buildings (high-rise, low-rise, commercial, residential), bridges, stadiums and arenas, industrial facilities and transmission towers, with:

- High strength-to-weight ratio: Steel is a strong material that can support large loads with a relatively small cross-sectional area. This makes steel columns lightweight and reduces the overall weight of the structure.

- Ductility: Steel columns can deform significantly before failing, which is important in areas with high seismic activity.

- Versatility: Steel columns can be fabricated into a variety of shapes and sizes to meet the specific needs of a project.

- Durability: Steel is a durable material that can withstand harsh weather conditions.

- Recyclable: Steel is a recyclable material, making it an environmentally friendly choice.

2.3 How to choose the right steel columns for your projects:

The right steel column for your project will depend on several factors, including:

- The load the column needs to support: The size and strength of the column will need to be sufficient to carry the weight of the structure above it.

- The height of the column: Taller columns will require a larger cross-section to maintain stability.

- The architectural requirements: Some projects may have aesthetic considerations that will influence the type of column chosen.

- Fire resistance requirements: In some cases, the column will need to be fire-resistant to meet building codes.

- Cost: The cost of the steel column will vary depending on the size, shape, and grade of steel used.

It is important to consult with a structural engineer to determine the right type and size of steel column for your project.

AM Industries Vietnam’s steel beams and columns fabrication

If you want reliable steel beams, steel columns or any steel structure fabrication services, contact the experts at AM Industries Vietnam. Our processes include stamping, welding, folding, bending, and finishing to match our exact requirements.

Working as a solution provider, at AM Industries Vietnam, we are completely focused on our approach, and it is reflected in our business process. Due to our committed approach, we are highly trusted by our clients.

We have served customers from Australia, New Zealand, the United States, Canada, and several countries in Europe and Asia. Our steel fabrication products are manufactured to international quality standards, with customized designs according to customer requirements.

Choose the service you want to consult and receive a quote completely free of charge:

Steel Components

Steel Structure

Metal Casting

Steel tanks/Silos

Stainless Steel Components

Quality Control Service

Sourcing