2020 is an unbelievable and unexpected year that it has brought great changes in many industries, including the metal fabrication industry. Our industry has held strong and the exciting technological developments. Our industry has held strong with amazing technological developments. In fact, there is a lot to look forward to as we enter 2021, including exciting industry trends to look out for.

So, what metal fabrication trends will lead this year? Let’s explore with us!

Automation – The strong trend in metal fabrication industry

There are still companies who remain unconvinced about the automation. They fear that it will take over their job opportunities. Other are considered about the initial investment and financial balance of incorporating automation processes into their company operation. But Covid-19 pandemic is forcing companies to speed up automation.

Furthermore, it is not the only reason. The advantages of automation are proving to far outweigh the disadvantages. Higher output and increased productivity have been two of the biggest reasons in justifying the use of automation.

For an example, a well skilled press brake operator might set up a complicated job in as little as 15 minutes, but an automatic tool change (ATC) press brake might do it in five.

While there are some hesitations out there, automation can bring substantial opportunities for the future of the metal fabrication and stamping industries if used strategically and effectively.

3D Printing – The growing trend in metal fabrication

3D printing is becoming more popular in the world of metal fabrication. In Australia, 3D printing and Metal fabrication is revolutionizing country manufacturing. 3D printing technology has made many improvements, all of which have contributed to enhanced opportunities for customization and efficiency.

From 2018 to 2019, the percentage of people using 3D printing FOR PRODUCTION increased from 38.75 to 51%.” It’s clear that 3D printing for production has reached a tipping point.

Cybersecurity – Metal Fabricators have to concern more

Cyber-attacks becoming more sophisticated, targeted, widespread and undetected. And the production line of steel fabrication can be also a popular target for cybercriminals. In fact, no matter which industry an organization operates in, it is important to know that they are at risk of being hacked.

Machines or line system are capable of being hacked as normal, so it is important to prepare ahead of time and implement the necessary software to protect against potential cyber threats.

According to IBM X-Force 2018 Threat Intelligence Index, the manufacturing sector is one of the more commonly hacked industries. So, many manufacturers are increasing their investments in cybersecurity technology.

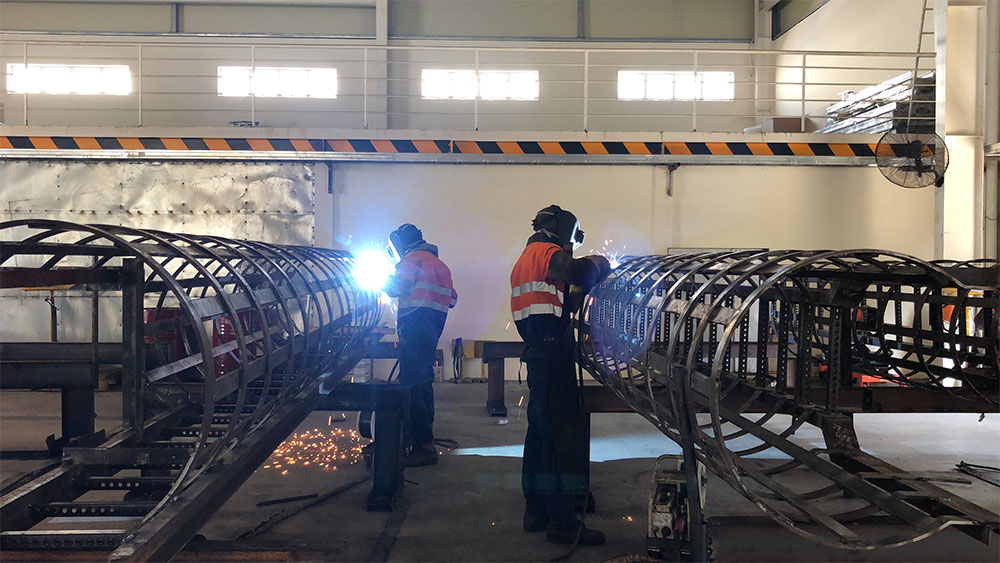

Outsourcing – The popular trend in the global metal fabrication industry

Metal fabrication process involves the production of metal tools and structures by machining, shaping and assembling steps. A finished metal product is completed by various metal spare parts and components from different fabricators. It’s a smart solution as they incorporate the strengths of multiple companies into one product.

Outsourcing offers huge benefits for companies who have limited resources and possibilities. It enables them not to worry about the fabrication process and quality management of materials while focusing on their areas.

A company outsourcing materials needs neither to invest heavily on equipment nor to maintain the workforce. Also, outsourcing companies usually specialize on one thing. In 2021, this trend may be further developed by the recovery of international shipping

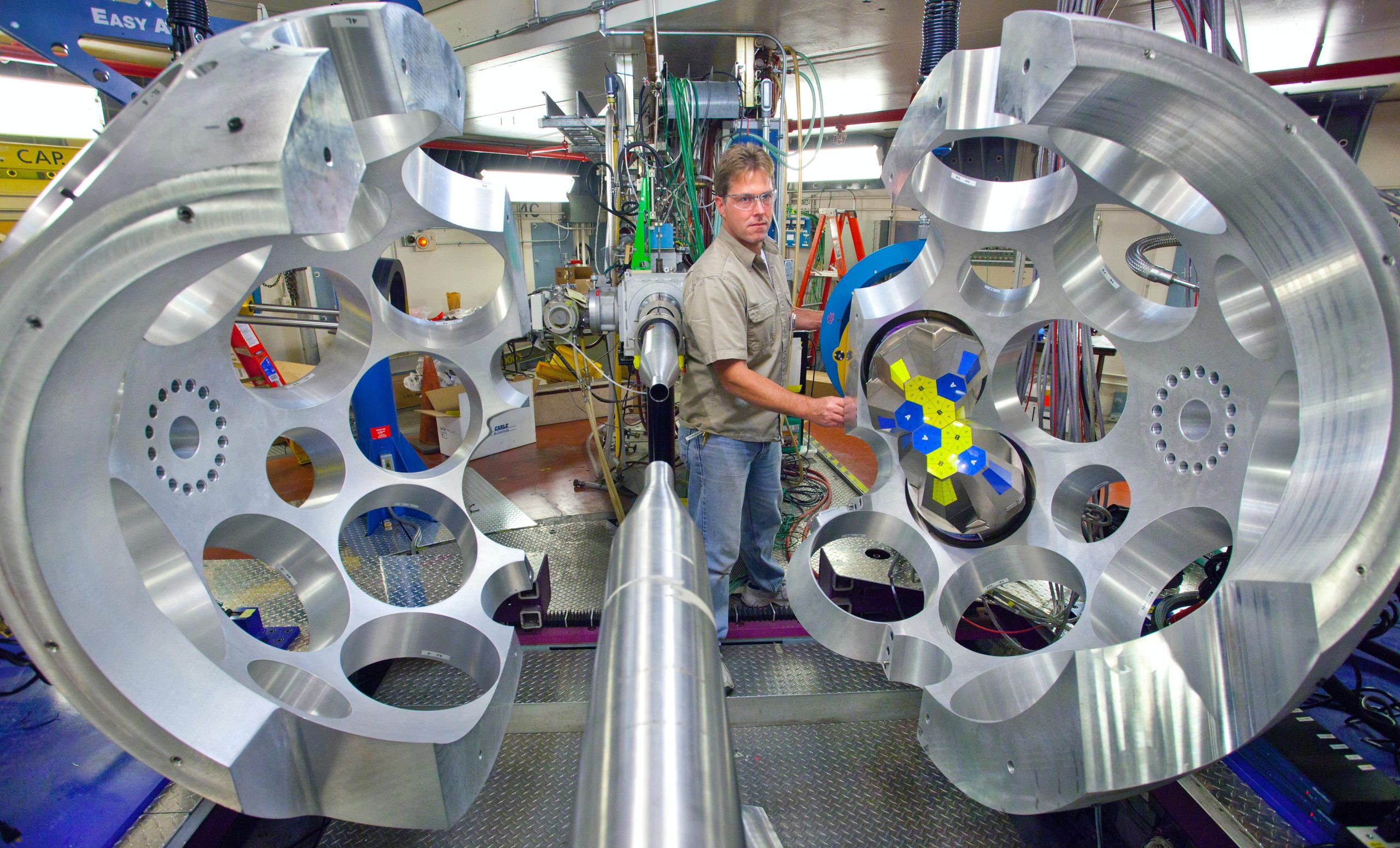

Robotics – The new trend in metal fabrication trend

Robotics is not only presented in science fictions and science shows, they are becoming a part of manufacturing industries. Nowadays, we can see the increasingly use of collaborative robots, also known as “cobots”.

According to Robotic Industries Association, cobots are providing manufacturers with safe, versatile, easy-to-use automation that supports human laborers. A cobot, or collaborative robot, is a robot intended for direct human robot interaction within a shared space, or where humans and robots are in close proximity.

Cobots are also trained differently than traditional industrial robots. Rather than programmed to a specific set of steps using programming tools, many cobots are trained by humans manipulating the arms and training by example.

While COVID made 2020 the year of predictable unpredictability, AM Industries Vietnam still believe that 2021 will provide new hope, new technology, and new innovation that will move the metal fabrication industry forward.

About AM Industries Vietnam

If you need high-quality steel parts, steel components, steel frame and steel fabrication Sydney, steel fabricators Brisbane, please contact us via email sales@aminds.com. At AM Industries Vietnam, we work with our customers to ensure you are satisfied with a high-quality product that suits your requirements.

We offer a wide range of steel components in various types and sizes, such as rung ladders, cradle stays bracket, mesh guard, sight glass & surround, ladder platform floor plate, collar, tube, pallet, sheds, steel ladders, steel box dumper…

Working as a solution provider, AM Industries Vietnam is completely focused on your needs. Therefore, we tailor our services appropriately to help you achieve the outcome best suited to you about the price, quantities and delivery time.

Due to our committed approach, we are highly trusted by our clients from Australia, America, Europe and other regions. It has further helped us to achieve a respectful position among our competitors.

Contact us today for a quote based on your requirements. If you need help, our experienced engineers are available to help determine the requirements for your specific project.

References:

https://news.daytonrogers.com/5-metal-fabrication-trends-predicted-to-dominate-2021

https://www.forbes.com/