Metal fabrication is the process of shaping, cutting, welding, and assembling metals such as steel, stainless steel, copper, aluminum, and zinc to create finished products, structures or spare parts. A skilled metal fabricator not only transforms raw materials into usable parts but also ensures precision, durability, and compliance with international standards.

Vietnam has become one of the most attractive destinations for metal fabrication thanks to its competitive manufacturing costs, strong supply chain, and experienced workforce. Wondering which metal fabricator in Vietnam is right for your budget and project standards? Check out the list of 10 below!

OVERVIEW OF THE METAL MARKET IN VIETNAM 2025

In 2025, the metal fabrication market in Vietnam is still in a period of strong growth and expansion, despite many challenges in terms of raw material costs, export taxes, import competition, etc.

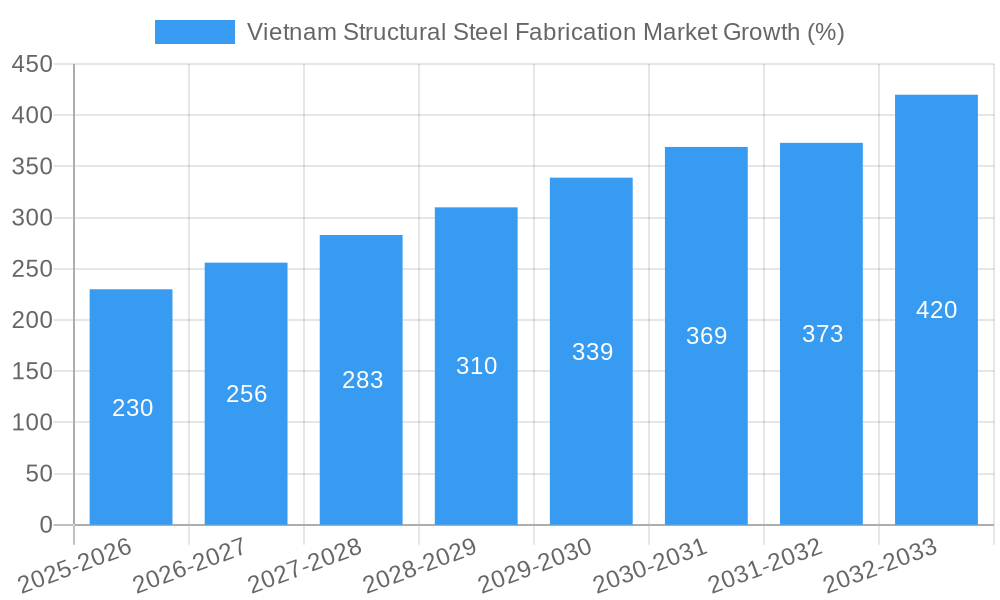

With domestic product reaching about 15.8 million tons in the first half of the year and consumption almost equivalent. Exports remain significant, with 6.4 million tons worth over 4.2 billion USD exported in the first 7 months of the year, although falling global prices have reduced export value. The steel structure manufacturing market alone is forecast to reach 3.05 billion USD by 2025, growing by more than 8% annually until 2030.

Looking ahead, Vietnam will continue to attract foreign investment to become one of the leading metal fabricator locomotives in the region, while domestic companies adopting green transformation and automation will enjoy a competitive advantage in both domestic and international markets.

WHY SHOULD CHOOSE A METAL FABRICATOR IN VIETNAM?

Choosing a metal fabricator in Vietnam offers global businesses a strategic advantage in terms of quality, cost, and reliability. Here is a summary of why Vietnam is a compelling choice for metal fabrication partners:

1. Low-cost production:

Vietnam has a young, skilled, well-trained labor force with low cost, and experienced in metal fabrication processes such as cutting, welding, machining, casting and assembling. Welders and metal fabricators often have international certifications, which help businesses reduce production costs and increase price competitiveness without affecting quality.

2. Quality and production capacity:

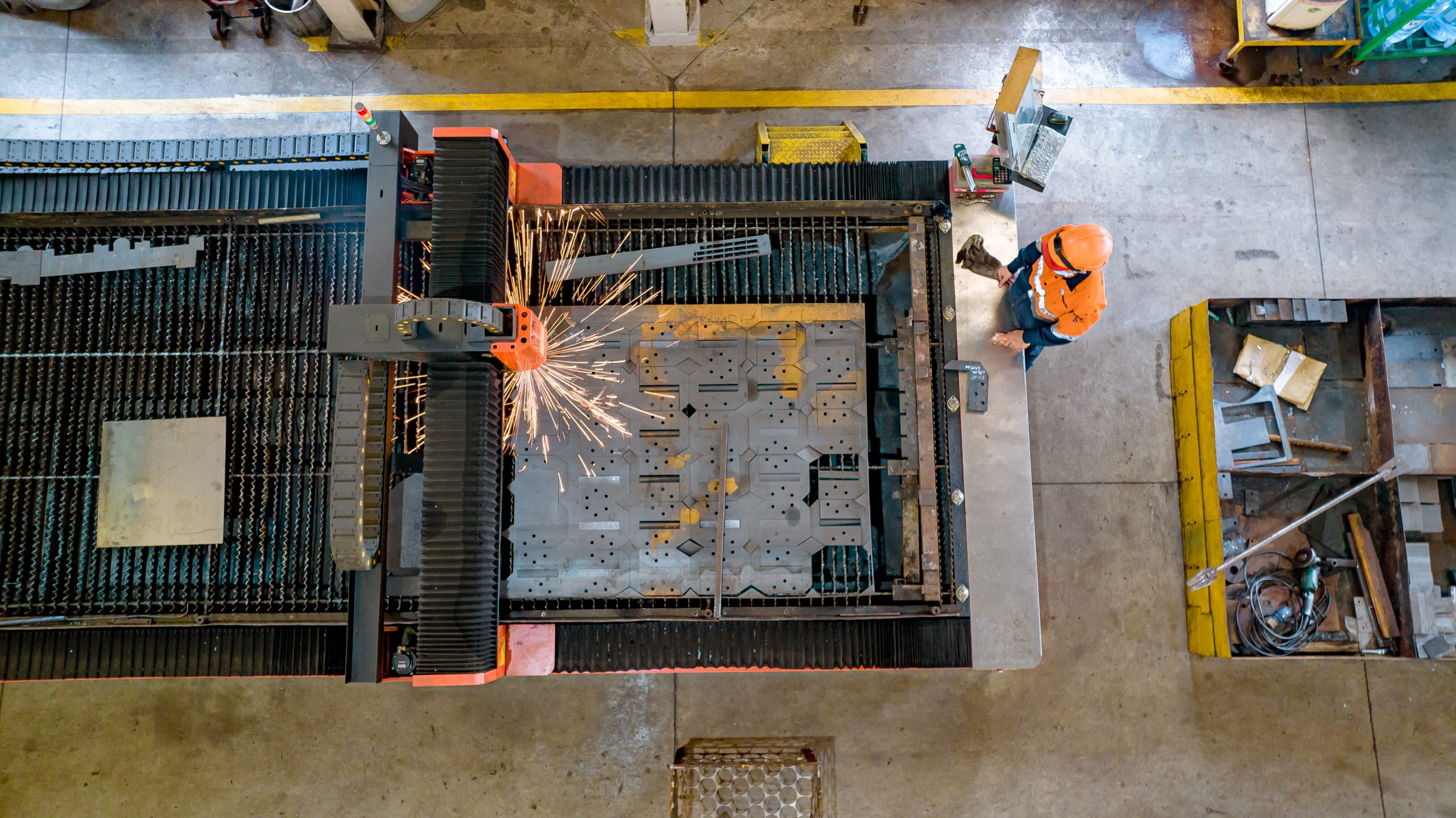

Many metal fabricators in Vietnam have invested in advanced, automated machinery and technology such as laser cutting machines, automatic welding robots, etc. Because of strong supply capacity and diverse sources of supply, businesses ensure accuracy, shorten production time and meet quality and durability standards of Australia, the US, Europe, etc.

3. Strategic location and logistics:

Vietnam is located near important international sea and air routes, proficient in logistics, packaging, and documentation. Large industrial parks and seaports are heavily invested, favorable for export, turning Vietnam into a potential metal fabricator in Asia.

4. Tax policy and supply shift:

The trend of shifting production and imports from China to neighboring countries is stronger than ever. Regarding tariffs, Vietnam is a member of FTA, helping to reduce or eliminate tariffs on exports. For the US market, tariffs on steel from Vietnam have been adjusted to a much lower level than China, increasing competitive advantage.

5. Consumption trends and green transformation

As global consumers demand lower carbon solutions, many Vietnamese manufacturers are investing in technology to produce cleaner products, energy efficiency and sustainable operations.

TOP 10 METAL FABRICATOR IN VIETNAM 2025

Below are 10 trusted metal fabrication companies in Vietnam for 2025, known for their quality, technology, and international standards compliance.

1. PEB steel

PEB Steel is a pioneer in the field of pre-engineered steel buildings in Southeast Asia, specializing in large-scale industrial structures, warehouses, and logistics centers.

2. ATAD Steel Structure Corporation

This is one of the most recognized names in Vietnam’s industry market, ATAD offers design–fabrication–installation solutions, serving commercial and industrial projects worldwide.

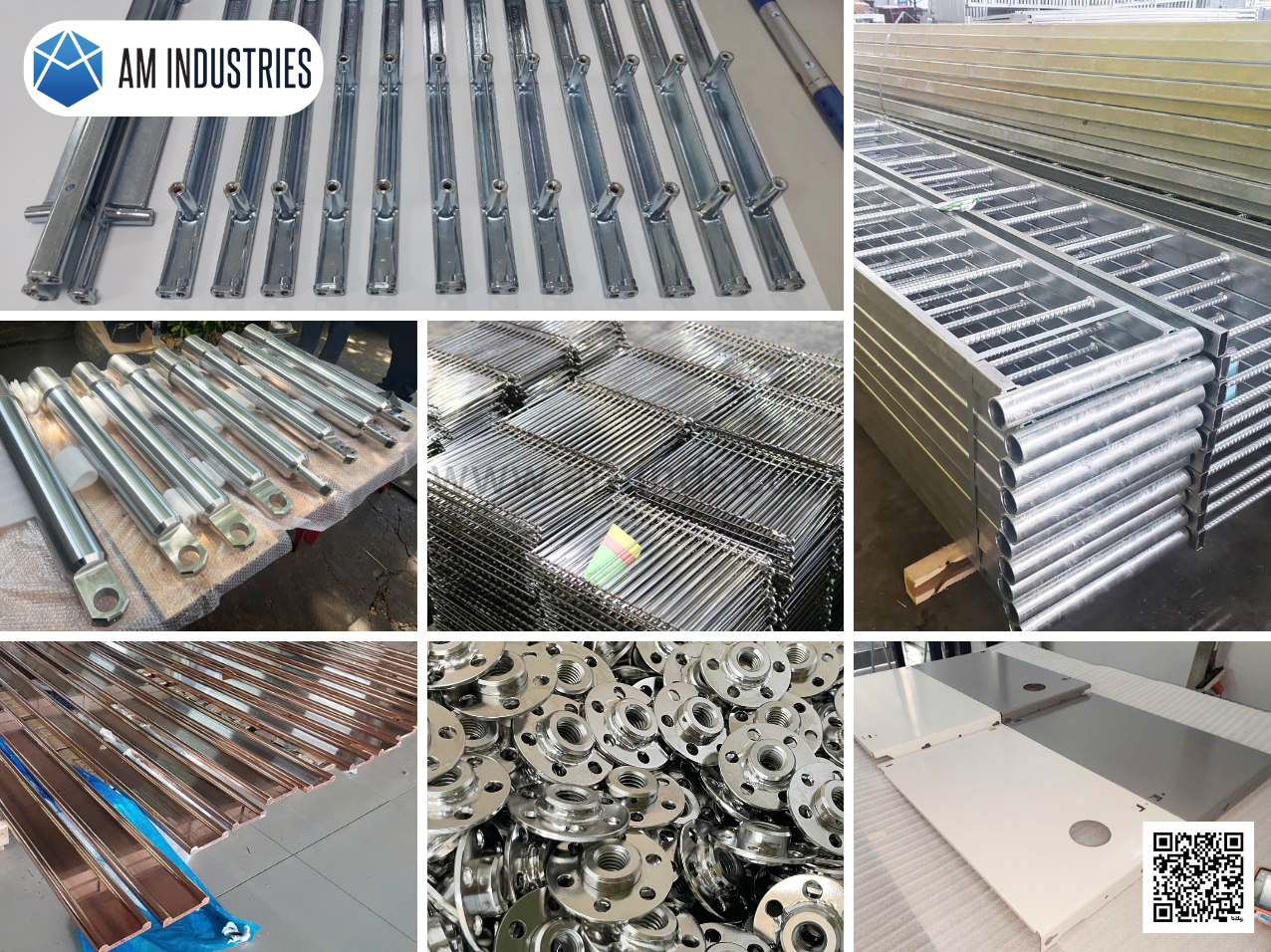

An Australian-owned, Vietnam-based manufacturer providing high-quality metal components, steel structures, metal casting and OEM fabrication services. AM Industries is trusted for its strict quality control (AS/NZS 5131, ISO 9001, ASTM, EN standards), global delivery network.

4. Metalic Vietnam

5. Australian General Engineering Vietnam

6. Fabtek

7. Universal Steel Fabrication Vina-Japan Co., LTD

8. Vietnam Metal Hardware

9. NS BlueScope Vietnam Ltd.

10. Nhat Nam Mechanical

AM INDUSTRIES – YOUR TRUSTED METAL FABRICATOR IN VIETNAM

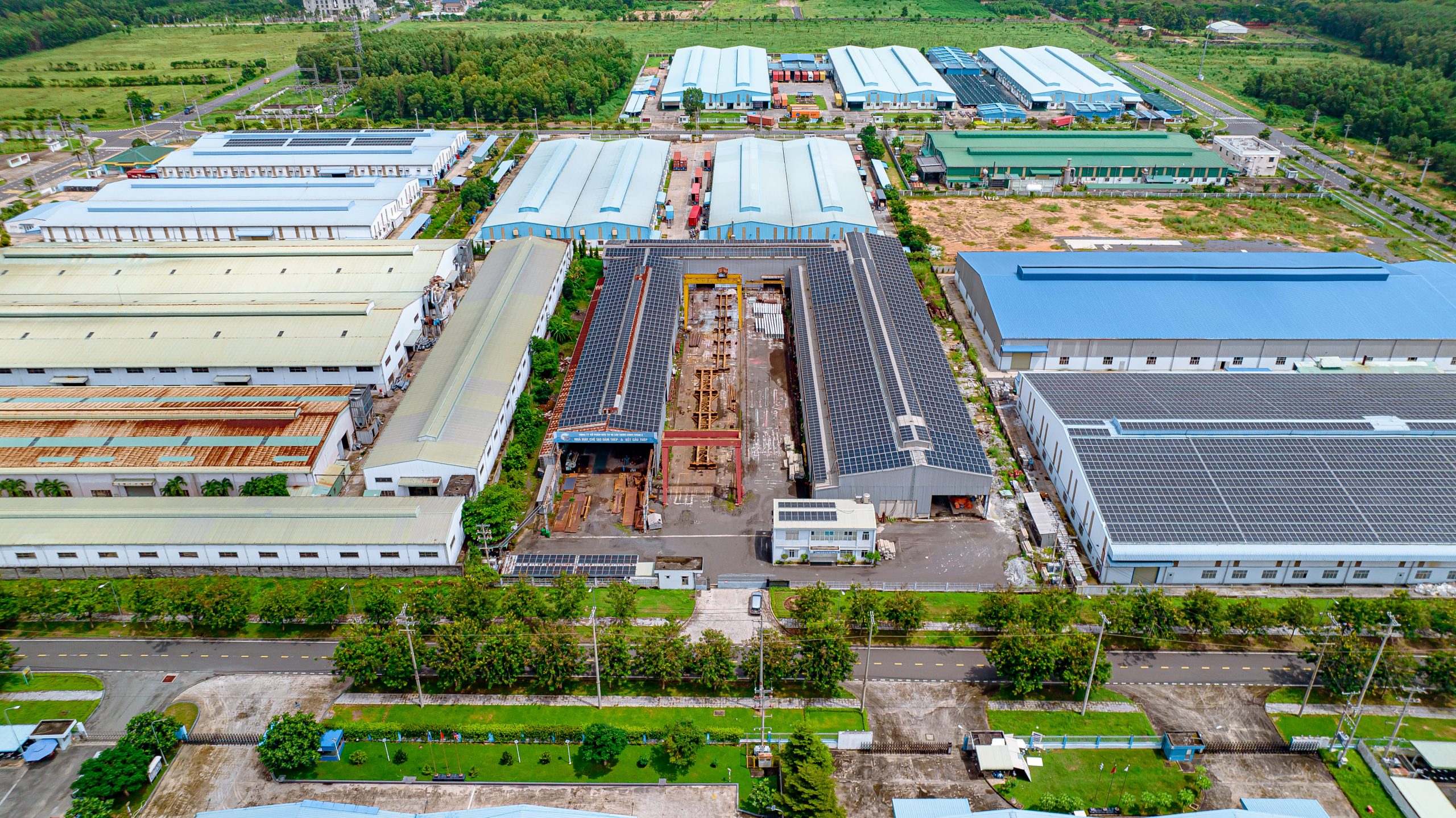

As mentioned in the list above, AM Industries is known as one of the most promising and reliable metal fabricators in Vietnam. With two large manufacturing plants in the Dong Nai Province and a representative office in Ho Chi Minh City, we combine world-class manufacturing with local efficiency to deliver high-quality products at competitive costs.

What Makes Us the Top Metal Fabricator in Vietnam:

- Quality Control Services: All manufacturing activities are carried out and strictly quality controlled according to Australian, American and European quality standards, ensuring durability, safety and precision.

- Custom Engineering: From metal components and steel structures to metal casting and metal sourcing in Vietnam, we provide tailored solutions based on your technical drawings and requirements

- Global Experience: Over 656 projects delivered to 30+ countries including Australia, New Zealand, the USA, and Europe since 2018.

- Competitive Advantages: cost-effective manufacturing, strong communication and customer services, on-time delivery, and long-term collaboration focus

What We Offer:

-

Metal Components – Precision-engineered spare parts from steel, stainless steel, aluminum, bronze, and zinc.

-

Steel Structures – Custom fabrication for industrial plants, warehouses, and mining projects.

-

Metal Casting – High-performance castings for heavy-duty applications.

-

Metal Procurement in Vietnam – Access to trusted local suppliers, ensuring quality raw materials and finished products

AM Industries Vietnam is more than a metal fabricator — we are your strategic partner for sustainable, cost-effective, and high-quality metal solutions. Whether you need small-batch production or mass manufacturing, our team is ready to support your project from start to finish.

👉 Contact AM Industries today to work with the top metal fabricator in Vietnam.