Automotive parts manufacturing is the process of creating the individual components that make up a car, truck, or other motor vehicle. These components range from small parts like nuts and bolts to more complex parts like engines, transmissions, and suspension systems.

According to Expert Report in 2023, the automotive parts manufacturing market is expected to grow by about 6.56% compared to 2023 and gradually increase until 2030.

With a significant growth rate in the use of automobiles, more and more manufacturers are paying attention to the production and processing of original components for automobiles across regions such as Asia, Europe, Australia, America,… Find out with AM Industry Vietnam to learn about 5 trends that are expected to increase in 2024 in the automotive parts manufacturing industry in particular and the fabrication industry in general.

5 game-changing trends in automotive parts manufacturing industry

1. Electric Devices (EVs) Are Gaining Popularity

The trend of converting to EVs in the auto industry is expected to have a strong impact on auto parts manufacturers. Demand for components related to electric vehicles will increase, while some parts and components of traditional cars will decrease.

Conversion components related to electric vehicles are on the rise, such as: electric motors, power electronics, battery systems, charging infrastructure, electric power steering systems, etc. Auto parts manufacturers can explore these opportunities to diversify their product portfolios and take advantage of the growing electric vehicle market.

2. Autonomous Driving Revolution

Self-driving cars have the potential to revolutionize numerous industries, including auto part manufacturing. This groundbreaking technology will lead to the implementation of new production processes, resulting in various advancements in techniques and production machinery. It is imperative for auto parts manufacturers to stay abreast of these changes and embrace new technologies in order to remain competitive in the industry.

3. Consumers Supporting Sustainable Practices Product

Environmental consciousness is no longer just a passing trend; it has become a crucial mandate. Looking ahead to 2024, the automotive industry is unwavering in its commitment to sustainability. With this growing environmental awareness, there will be an increased demand for parts crafted from recycled or sustainable materials.

Manufacturers are actively working towards reducing their carbon footprints by incorporating eco-friendly production processes and materials. Embracing hybrid and electric vehicles is just one piece of the puzzle, as there is also a significant shift towards using recyclable and biodegradable materials in auto part manufacturing.

Check out more sustainable trends in the mining industry here!

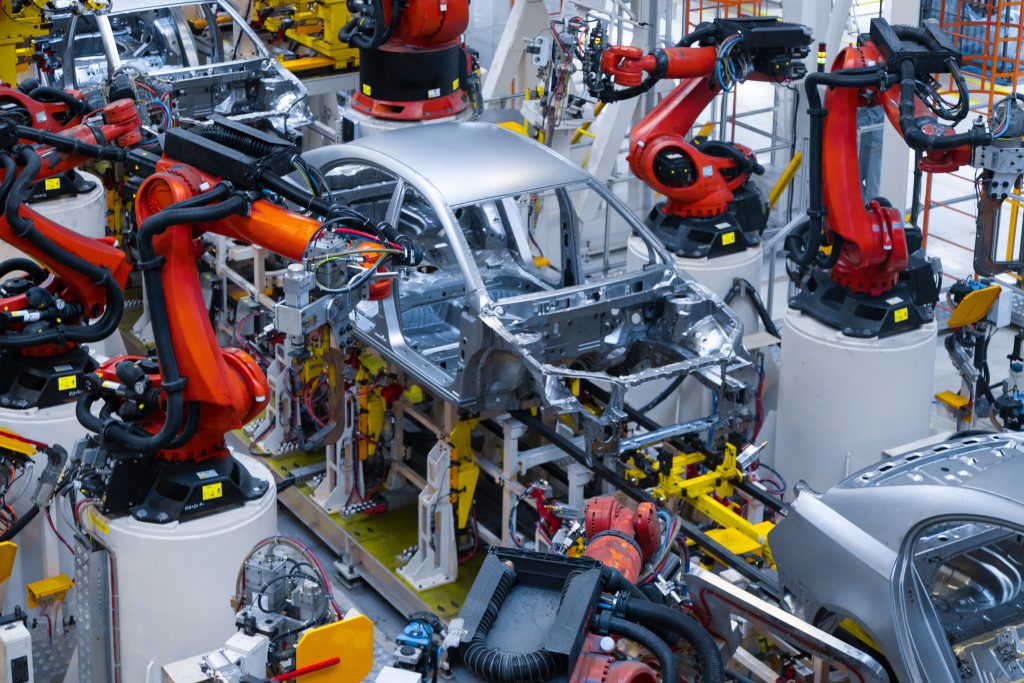

4. Hyper automation and integrated software

Hyper-automation and software integrations are also changing the way manufacturers operate. By using machines, robots, sensors and software to quickly perform tasks that were previously performed by humans, the process has increased productivity, quality, safety and efficiency. At the same time, it also reduces costs, human resources, and avoids errors and waste.

The integration of Internet of Things (IoT) technology in auto part manufacturing will require the fabrication of parts that can support connectivity, such as advanced infotainment systems and telematics devices.

5. 3D Printing Revolutionizes Manufacturing:

The incorporation of 3D printing into the manufacturing process of auto parts has the potential to completely transform the production landscape. By enabling greater customization, intricate designs, stylish aesthetics, unprecedented uniqueness, and faster turnaround times, this revolutionary technology empowers manufacturers to stay ahead of the curve and gain a competitive advantage.

AM Industries is ready to change and catch up with 2024 automotive parts manufacturing trends

At AM Industries Vietnam, we stay vigilant in keeping up with the latest trends and adjusting our business operations accordingly. By harnessing our inherent cost advantages and integrating advanced automated machinery systems, we continuously innovate to offer you the most fitting components. Rest assured, our products not only meet your need but also the quality standards set by AU, US, NZL, and more.

AS a leading manufacturing partner in Asia, we are committed to providing you with suitable solutions with automotive parts, metal parts, steel components, steel structures and other metal processing services to stay ahead of innovation trends of the manufacturing industry.

Let us be your trusted partner for manufacturing solutions in 2024 and beyond. Contact us today to find out how we can help you achieve your goals.