How mining equipment can both achieve optimal capacity and efficiency, while also being environmentally sustainable is something that the “leading” countries in the mining industry today, like Australia, Canada, and the United States, are interested in.

In addition to the mining and development policies implemented by national governments, businesses are adopting “Green Technology” and innovative trends in the field of mining equipment. These technological advancements are instrumental in mitigating waste production, enhancing operational efficiency, and minimizing the environmental impact of human activities.

See more emerging trends and technology here!

As one of the metal fabricator, AM Industries Vietnam also applies these advanced technologies in manufacturing metal components and metal parts for mining machines. We ensure the delivery of top-quality components for mining equipment that comply with environmental standards.

So what are these “Green Technologies”? Let’s explore through the article below!

TOP 3 GREEN TECHNOLOGIES FOR MINING EQUIPMENT TO PURSUE SUSTAINABILITY IN MINING INDUSTRY

Mining equipment in the mining industry plays a very important role. The improvement of mining equipment not only limits environmental pollution and enhances worker safety, but also creates great profit potential.

These improvements have a significant impact and slowly change the manufacturing industry in general, and the mining industry in particular.

1. Replace electric and battery-powered mining equipment instead of diesel engines

Battery-powered mining equipment is often equally powerful to replace diesel-powered options. Replacing diesel engines with electric ones can significantly reduce the amount of CO2 generated by mining.

The types of battery-powered machines in use today are trucks, rigs, and wheel loaders. There are already several electric mining vehicles available in the market, such as the Komatsu’s electric mining dump truck.

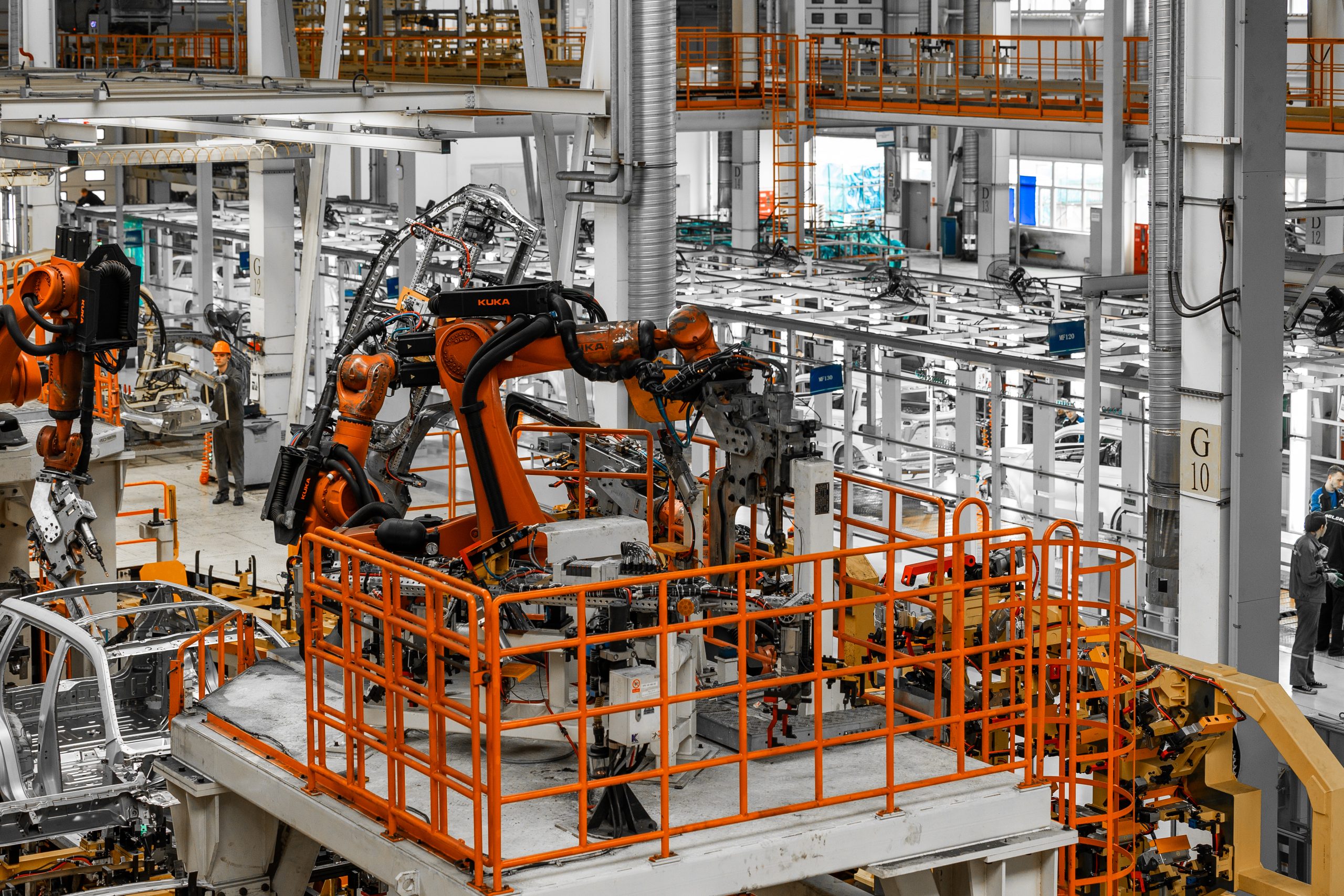

2. Using automation mining equipment: Applicable to both underground mines and open pit mines

Automated machines operate under stricter protocols than human operations, minimizing unnecessary use. Theoretically, this approach extends the life of the machine, reduces energy emissions during operation, and uses inputs more efficiently.

New technologies reshaping the field include automated mining trucks and rigs, remote control centres, automated drilling and training systems…

Automated mining trucks: They can operate almost continuously, aside from breaks for refueling and maintenance. They benefit from a longer lifespan, reduced fuel use and fewer maintenance costs.

Automated drilling and tunnel-boring systems: the system automatically targets more accurately underground, reducing wasted drilling time and maximizing output.

Automatic robots: replace humans in movement, so in addition to the accuracy factor when designing robots, they must meet some special requirements such as the ability to receive and transmit signals remotely, provide people with information found in mines

3. Using digital technology

Cloud network integration technology: Integrating the Internet of Things and cloud computing to perform identification, positioning, monitoring and intelligent management functions.

Many mines now apply new technologies such as AI and 5G to automate production. In cobalt mines, diverse mining equipment includes ore excavators and automatic sorting – processing machines.

Use 3D simulator: using simulations at the mine design stage to test different solutions before implementation

Stream analyzer and online element

AM Industries Vietnam supplies metal components and spare parts for mining equipment that meet green solutions

Our team has more than 20 years of experience and is highly qualified, grasping trends in time, we ensure to meet the increasingly demanding requirements of the mining industry. With a strict production process at the factory in Vietnam, all requirements for your products and components will be completed quickly and up to international quality standards.

We can supply a wide range of mining spare parts and components used for mining equipment including:

- Mining Drills: Rotary Drilling Rigs and Rock Drills

- Mine blasting tools

- Crushing equipment

- Online elemental feeding, conveying and analysis equipment

- Large mining truck

- Engine sorters and more

- Steel platform system

|

|

|

| Steel Platform System for Mining Equipment | Steel Platform System for Mining Equipment | |

|

|

|

| Transfer Hopper | Transfer Hopper | |

|

|

|

| Components by metal stamping | Components by metal stamping | |

|

|

|

| Components by metal casting | Components by metal casting | |

At AM Industries Vietnam, we want to be your source for all machinery, spare parts, and metal components for your mining operation. We can assist you in finding whatever you require, be it new equipment, steel components, parts, or services.

If you require any further information, please don’t hesitate to contact us via email contact@aminds.com