Hot Dip Galvanized is the leading protective coating for steel framing. Structural steel has been the material of choice in the building market for decades because of the numerous benefits it provides. While steel offers an effective and efficient framing system for the building envelope, the hot-dip galvanizing of both interior and exterior elements is one method to provide a durable and maintenance-free corrosion protection system for generations.

What Is Hot Dip Galvanized Steel Frames?

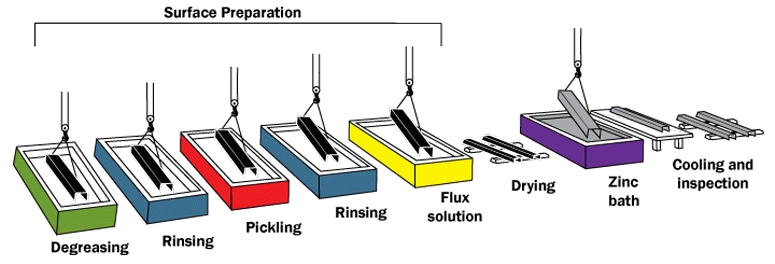

Hot-dip galvanizing (HDG) is the process of coating fabricated steel members by immersing it in a bath of molten zinc at high temperature. There are three fundamental steps in the hot-dip galvanizing process; surface preparation, galvanizing, and inspection.

The anticorrosion life is directly proportional to the thickness of zinc layer, the professional level of production and stable quality level. The galvanized coating provides outstanding abrasion resistance. Where there is damage or minor discontinuity in the sealing coat of zinc, protection of the steel framing is maintained by the cathodic action of the surrounding galvanized coating.

Therefore, galvanized steel framing is a common material used for outdoor structures. For examples, the oceanfront is a beautiful but expensive place to live. And as it turns out, it’s also one of the most difficult places to use metal in outdoor architecture. The salt and moisture of the seaside makes long-lasting construction a challenge. Galvanized Steel is one of the 4 popular materials for outdoor architecture.

Half of the galvanized steel frame are used after the whole surface is galvanized, but some parts of the surface of the galvanized steel framing are not required to be galvanized. In order to ensure the friction coefficient, the friction joint surface is not galvanized. But recently, there is some proper treatment after galvanizing which can be adopted to ensure the friction coefficient.

During the manufacturing of hot-dip galvanized steel frame, the QC process will pay attention in common problems such as component shape, casting, bolt connection component, steel composition, assembly of different materials, local parts without galvanized parts, etc.

Main Material of Galvanized Steel Framing

The galvanized steel frame takes the constant section or variable section H-shaped, I-shaped steel as the main load-bearing body, C-type and Z-type purlins and the support between columns as the auxiliary connecting parts, is fixed by means of bolts or welding, and the roof and wall are enclosed by color profiled steel plates.

Structural steel is made from hot rolled structural steel sections with fully welded connections making them stronger and more robust. Besides that, C-Purlin structures, made from lightweight cold rolled ‘C’ sections with bolted connections, making them susceptible to twisting and movement.

Most cold-formed steel is galvanized by unwinding coils of cold rolled steel and feeding the sheet continuously through a molten zinc bath at speeds up to 600 feet per minute (200 meters/minute).

As the steel exits the molten zinc bath, air “knives” blow off the excess coating from the steel sheet and control the coating thickness to the specification requirement. The coated sheet steel is chemically treated (passivated) to protect against storage stain and, if requested, oiled and recoiled for shipment to the fabricator.

AM Industries Vietnam’s steel frame fabrication

If you want reliable steel frames, steel roof truss and steel structure, contact the experts at AM Industries Vietnam. Our processes include stamping, welding, folding, bending, and finishing to match our exact requirements.

Working as a solution provider, at AM Industries Vietnam, we are completely focused on our approach and it is reflected in our business process. Due to our committed approach, we are highly trusted by our clients.

We believe in an industrial world made of trust, passionate and dedicated people. We word to achieve this with an open-minded, quick and customer-centered approach.

Want to learn more about our steel fabrication services in Vietnam? Contact us today for a quote based on your requirements.