Worsening skilled labor shortages will be “the challenge of the decade” for Australia’s under-pressure construction industry, a new report has warned. Australia’s building labor shortages are not unique, with the US, UK, Ireland, and mainland Europe all experiencing a similar strain on their building sector workforces.

Construction job vacancies have increased by a massive 80 percent since late 2019. It is forecast that by 2023 there will be more than 100,000 unfilled roles in the sector.

Understanding this problem, here are 3 ways to deal with the labor shortage that AM Industries Vietnam is able to provide.

Providing optimal steel structure solutions to save money and installation cost

Australia’s construction industry is facing a critical worker and supply shortage which could see all projects brought to a halt in a matter of weeks. ARK Joinery owner Andrew Jhavery told Today Newspaper there is a critical skills shortage in the country at the moment, but the biggest pinch is being felt with materials: “We are looking at eight to 12 weeks and we will be running out of timber products in Australia,”

To help complete projects with less manpower, AM Industries Vietnam is able to provide pre-engineered steel building components, conveyors, silo/ tanks, metal casting and other steel spare parts. Steel buildings for sheds and houses are the ideal choice for prefabricated construction because it is lightweight and can be cut to precise specifications. You can read more about steel building advantages here.

Our steel structure products alleviate the problems associated with the labor shortage by allowing the work to happen where the workers are — in Vietnam factories — rather than at job sites scattered across Australia or the USA. We hire workers with the right skills and schedule a steady stream of projects to keep the schedule tightly and save costs efficiently.

Our facilities producing steel components and parts are located near highways, airports, and seaports for easy transit. And while our factories may be more than 6,000 km from a job site in Southern Australia, the location simply doesn’t matter because transit time is factored into project schedules. Plus, transporting pre-engineered steel building components costs far less than relocating a team of workers to a job site for several weeks or months.

Our Project Management, Ms. Mai says that pre-fabrication can be as much a workforce development strategy as a competitive business advantage for construction firms. That’s because workers want safe and predictable environments.

Fabricating and controlling production quality compliant with different standards

We have experience in fabricating and controlling production quality compliant with Australian Standards, American Standards, and European Standards.

By managing the entire process, we can control costs, stock, and quality to consistently deliver projects on time and on budget. Our steel structure fabrication service has already afforded significant efficiencies to savvy building owners and could save up to 20% of total construction cost than your local services.

AM’s Galvanized Steel Roof Truss

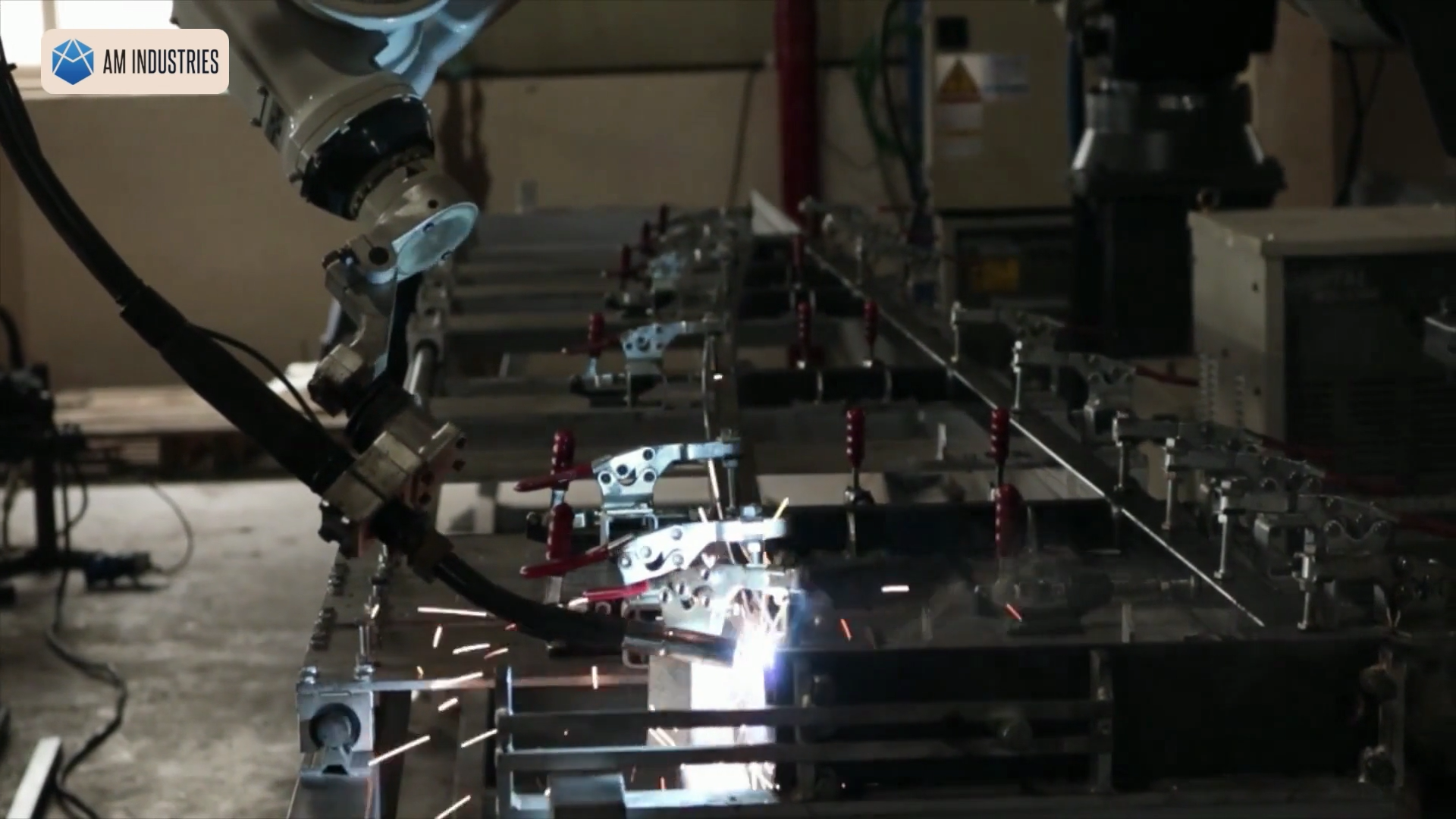

At AM factory, robotic welding machines are involved in the manufacturing process that automates the welding process to increase accuracy, enhance safety and reduce the time needed to complete each project. It not only increases our production effectiveness but also avoids these injuries and prevents further harm, which will turn our factory into a safer work environment. You can see our welding robotic clip in YouTube.

We also implement digital transformation as one way to support us in improving productivity. Our General Manager, Ms. Thanh shared: “Integrated technologies save time and money and improve project efficiency and safety by allowing our project team to easily collaborate and share information, whether they are in the office or out in the field.”

We have the experience to work and export steel structures and metal fabrication products to various companies in APAC (Australia, New Zealand…), the USA, Canada, EU, and other regions.

Owning skilled workers with affordable prices

The high levels of demand for skilled fabrication and installation workers can put a lot of pressure on construction firms in Australia and the USA.

As a trust metal fabricator, we are supplying steel components, steel structure, metal fabrication, industrial services, and sourcing from Vietnam to Worldwide.

Firstly, we have enough skilled workers to complete jobs within the tight timeframes; don’t face with labor shortage issues. Secondly, the high-quality control issues are adopted by those who had full experience in metal fabrication. We ensure the project quality by a team of professional site engineers with 10+ years of experience and skilled workers.

Moreover, we have built a strong supplier network in Vietnam, Thailand, China, and other countries and facilitate the development of the product line system to ensure consistent quality, supply, and competitive prices.

AM Industries Vietnam – Your trust partner in steel trusses fabrication

AM Industries Vietnam sources the following categories of materials:

- Steel components

- Steel structure

- Stainless steel components

- Kitting & assembly

- Steel water tanks / Steel silos

- Metal casting

- Residential & commercial building products

- Quality control services

- Partnering

- Sourcing

We believe in an industrial world made of trusted, passionate, and dedicated people. We work to achieve this with an open-minded, quick, and customer-centered approach.

Please feel free to get in touch with us for all your inquiries.