TRUSSES

A truss is essentially a triangulated system of straight interconnected structural elements. The most common use of trusses is in buildings, where support to roofs, the floors, and internal loadings such as services and suspended ceilings, are readily provided. The main reasons for using trusses are:

- Long span

- Lightweight

- Reduced deflection (compared to plain members)

- Opportunity to support considerable loads.

The penalty, however, is increased fabrication costs.

The article describes alternative forms of truss, where and why different forms might be appropriate, and introduce design considerations. Primarily, pin jointed trusses are discussed, with some discussion of rigid-jointed Vierendeel trusses.

DEFINITION OF A TRUSS

A truss is essentially a triangulated system of (usually) straight interconnected structural elements; it is sometimes also referred to as an open web girder. The individual elements are connected at nodes; the connections are often assumed to be nominally pinned. The external forces applied to the system and the reactions at the supports are generally applied at the nodes. When all the members and applied forces are on the same plane, the system is a plane or 2D truss.

Overview of trusses packing process at AM Industries Vietnam

USE OF TRUSSES IN BUILDINGS

Trusses are used in a broad range of buildings, mainly where there is a requirement for very long spans, such as in airport terminals, aircraft hangers, sports stadia roofs, auditoriums, and other leisure buildings. Trusses are also used to carry heavy loads and are sometimes used as transfer structures. This article focuses on typical single-story industrial buildings, where trusses are widely used to serve two main functions:

- To carry the roof load

- To provide horizontal stability.

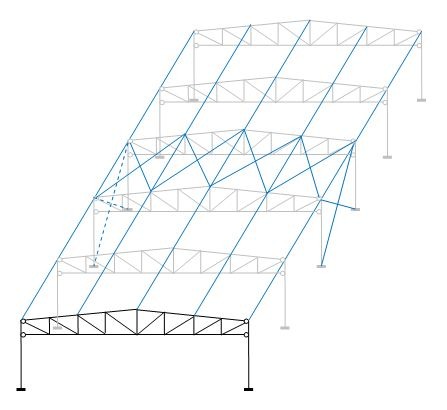

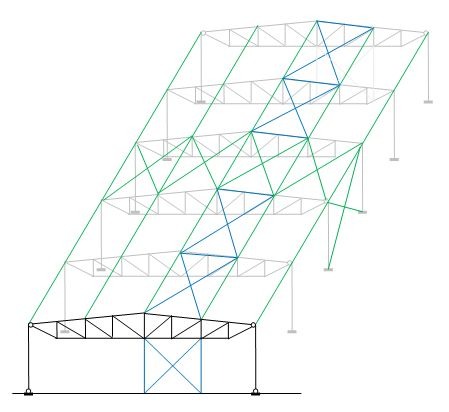

Two types of general arrangement of the structure of a typical single-story building are shown in the figure below.

Typical truss building arrangements

|

|

|

|

In the second case, (right) each truss and the two columns between which it spans, constitute a simple structure; the connection between the truss and a column does not resist the global bending moment, and the two-column bases are pinned. Bracing in both directions is necessary at the top level of the simple structure; it is achieved by means of a longitudinal wind girder which carries the transverse forces due to wind on the side walls to the vertical bracing in the gable walls.

Longitudinal stability is also provided by a wind girder in the roof and vertical bracing in the elevations. In the first case (left) the lateral stability of the structure is provided by a series of portal trusses; the connections between the truss and the columns provide resistance to a global bending moment. Loads are applied to the portal structure by purlins and side rails.

Sourced: Steel Construction

At AM Industries Vietnam, we are passionate about metal processing and manufacturing in which we operate. AM has developed the technology and professionalism that can advise you on high-quality products. We offer a wide range of steel components in various types and sizes, such as Rung ladders, cradle stays bracket, Mesh Guard, Sight Glass & surround, Ladder Platform Floor Plate, Collar, Tube, Pallet, Steel Ladders, steel box dumper …

And our company is ready to receive orders to design parts, components according to your needs, ensure the high quality that makes you satisfied with the accuracy of deviations, absolute accuracy, International standards. For further information and a full list of products, please contact us.

AM Industries Vietnam is an independent company supplying steel parts components, spare parts, steel structure, steel fabrication, industrial services, and sourcing from Vietnam and Asia to Worldwide.

Please feel free to get in touch with us for all your inquiries.